Other prestressing equipment

Strand Pusher

- Product ID:Other prestressing equipment

- WhatsApp:+8618837801688

- Mobile: +86-18837801688

- Tel: +086-0371-22331589

- Email: aomu.info@gmail.com

- Time: 2023-04-27 11:05:58

- FEEDBACK

product description:

Strand Pusher

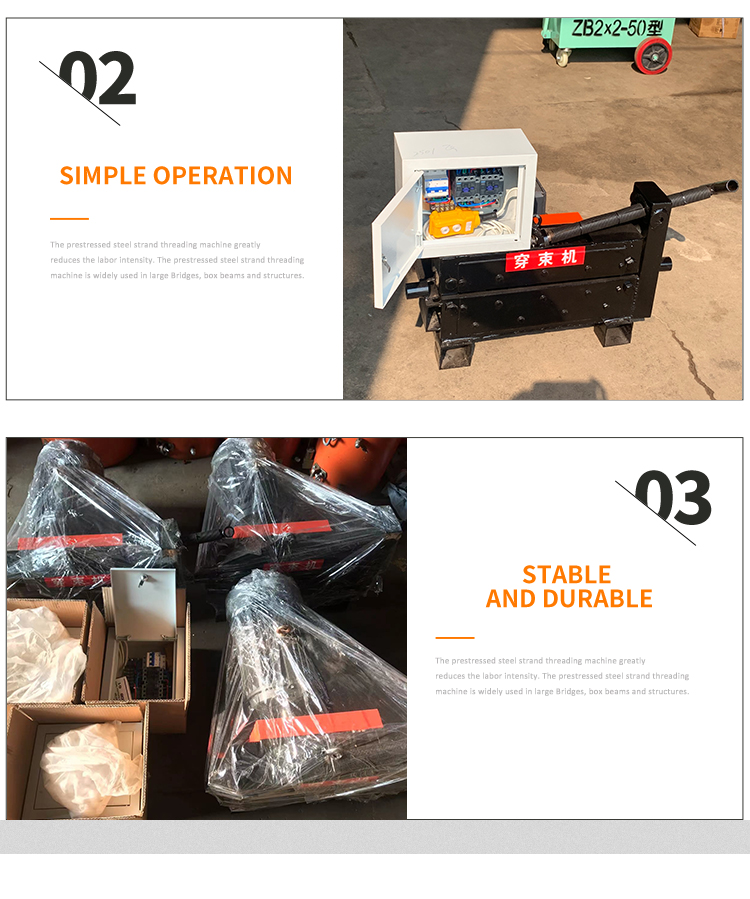

Steel strand threading machine is also called: steel strand threading machine, steel strand threading machine, steel strand pipe threading machine. The steel strand threading machine (prestressed steel strand threaded into the channel hole is referred to as threading cable) is driven by a machine, and the steel strand is clamped by the roller for transmission. It can be advanced, retracted, continuous transmission, or jog transmission.

Convey the speed of the steel strand with stepless speed regulation, convenient operation, reliable performance, and remarkable efficiency. The prestressed steel strand threading machine greatly reduces the labor intensity. The prestressed steel strand threading machine is widely used in large bridges and box girders with structures.

Features:

The speed of steel strand is continuously regulated, which is easy to operate and high in efficiency

2. Save labor and time, accurate data, save a lot of labor and material costs.

3. The equipment is small in size and light in weight, easy to transport, install and maintain.

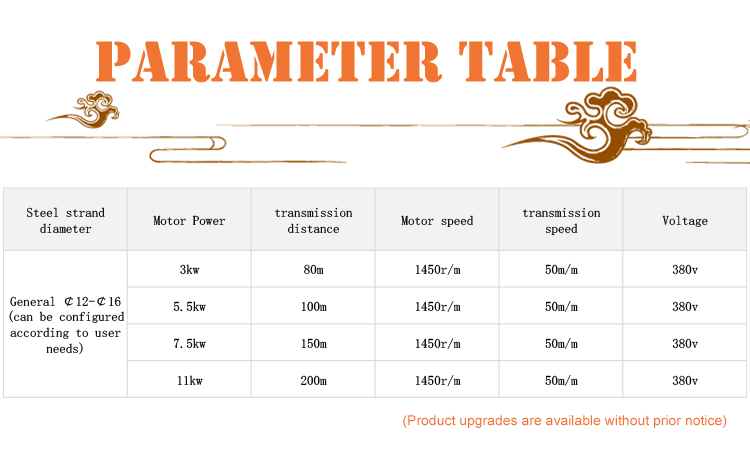

Technical Parameters:

Strand diameter Motor power Conveying distance Motor speed Conveying speed Voltage

General¢14-¢16 3kw 70M 1450r/m 50m/m 380v

(can be configured according to user needs)

General¢14-¢16 5.5kw 100M 1450r/m 50m/m 380v

(can be configured according to user needs)

General¢14-¢16 7.5kw 150m 1450r/m 50m/m 380v

(can be configured according to user needs)

General¢14-¢16 11kw 200M 1450r/m 50m/m 380v

(can be configured according to user needs)

Instructions:

Preparatory work before starting up:

(1) Check whether the electrical circuit is intact, and check the position of the oil level in the reducer.

(2) Check whether the direction of motor rotation is in line with the direction marked by the arrow on the casing.

(3) Turn on the power, debug and confirm the positive and negative rotation.

2. Normal work:

(1) Insert the steel hinge wire that has been laid on the shelf from the wire inlet of the machine, and click the wire inlet button switch to make the steel hinge wire slowly penetrate into the machine, enter the reserved hole along the conduit, and pass through the other end to reach the reserved tension. Pull to size and cut off with a handheld grinder.

(2) When the conveying distance cannot be reached, the pressing spring screw of the moving wheel on the machine can be adjusted to meet the working requirements, but the adjustment should not be too tight, so as not to aggravate the wear of the pressing wheel during operation and reduce the service life.

(3) When working, pay attention to whether the operation is normal. When any fault is found, stop the machine immediately, find out the cause and eliminate the fault before restarting.

CATEGORIES

LATEST NEWS

CONTACT US

WhatsApp: +8618837801688

Phone: +86-18837801688

Tel: +086-0371-22331589

Email: aomu.info@gmail.com

Add: NO.5 Jinming Avenue,Kaifeng City,Henan Provience,China