Other prestressing equipment

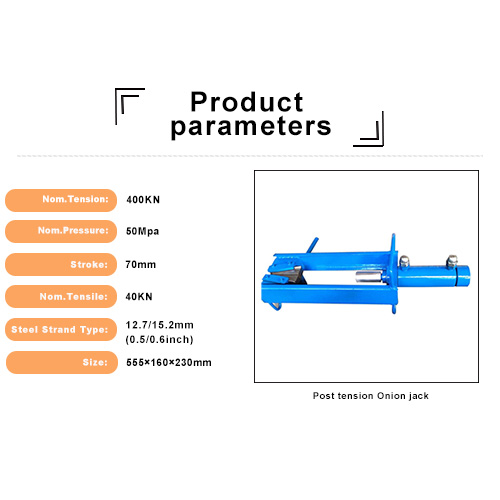

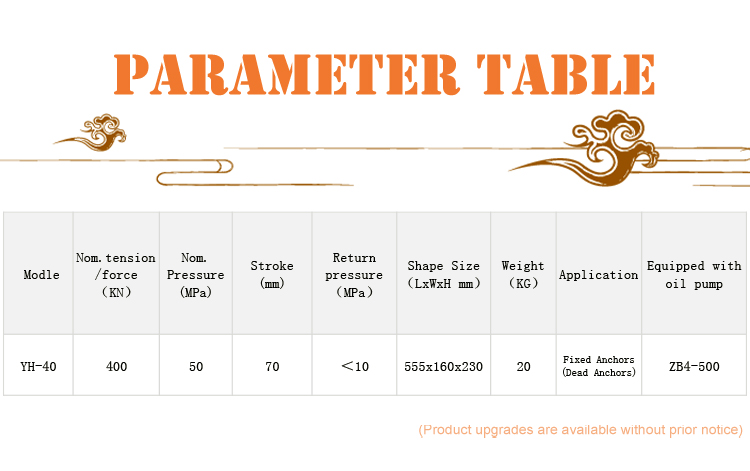

Onion Jack

- Product ID:Other prestressing equipment

- WhatsApp:+8618837801688

- Mobile: +86-18837801688

- Tel: +086-0371-22331589

- Email: aomu.info@gmail.com

- Time: 2023-04-27 10:59:20

- FEEDBACK

product description:

Onion Jack

The steel strand embossing machine is mainly used to press the fixed end of the prestressed steel strand into a pear-shaped loose flower shape, equipped with mesh, spiral bars or stirrups and other structural reinforcements,

The self-anchor anchor head is formed by gripping, extruding and anchoring between the embossed part of the steel strand and the concrete. It has the characteristics of small size, light weight and convenient operation.

working principle:

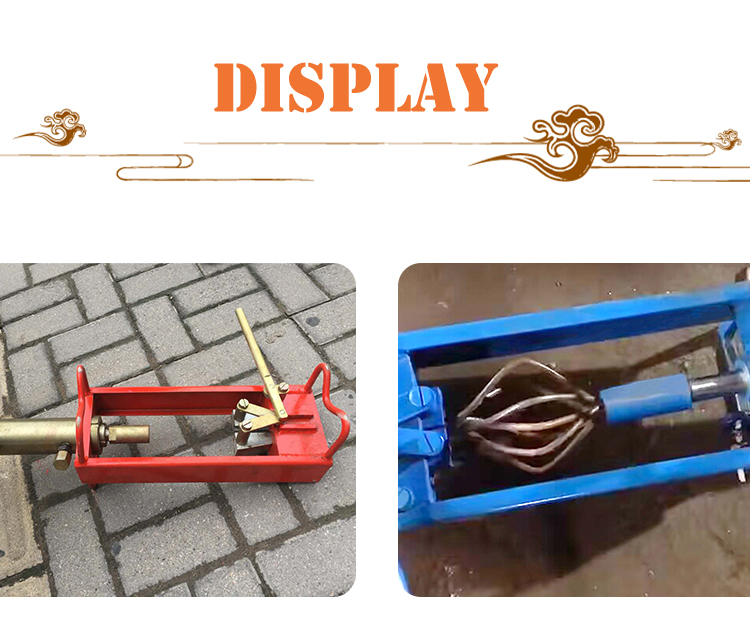

Extend the steel strand into the jacking head through the clamping steel strand wedge. When the hydraulic cylinder is filled with oil, the piston moves, and the jacking head moves together against the head of the steel strand.

At the same time, the wedge for clamping the steel hinge clamps the steel strand by the inclination, and as the piston moves, the wedge clamps the steel strand more and more tightly by the inclination.

In this way, when the piston moves into place, the steel hinge line between the clamping part of the wedge and the top will be pressed into a pear-shaped loose flower shape. Then the piston returns,

Move the hinge mechanism to drive the wedge to withdraw, and the steel hinge wire is taken out, and the embossing is completed.

Structural features:

1. The diameter of the piston head in the top pressure cylinder is relatively large, and the embossing work can be completed under relatively low pressure.

2. The frame is made of high-quality carbon structural steel plate with a thickness of 4mm, which has high strength and reliable welding.

3. The tool clip is made of 20CrMnTi material, which has a long service life.

Embossing machine operating procedures:

1. The steel strands are unloaded, the ends are flush, the flashing and burrs are removed, and the strands cannot be scattered.

2. Pull the handle of the steel strand embossing machine, the tool clip moves, and the two halves separate to allow the steel strand to pass through.

3. The steel strand passes through the tool clip and is inserted into the hole of the indenter.

4. Turn the handle, the tool clip moves, the two flaps close together, and initially clamp the steel strand.

5. Start the oil pump, the pressure head moves, the steel strand is pressed into a pear-shaped head, the oil pressure drops to zero, and the embossing is completed.

6. Oil enters the return cylinder, the piston resets, and the pressure head moves backward.

7. Pull the handle, the tool clip moves, and take out the steel strand with pear-shaped head.

CATEGORIES

LATEST NEWS

CONTACT US

WhatsApp: +8618837801688

Phone: +86-18837801688

Tel: +086-0371-22331589

Email: aomu.info@gmail.com

Add: NO.5 Jinming Avenue,Kaifeng City,Henan Provience,China